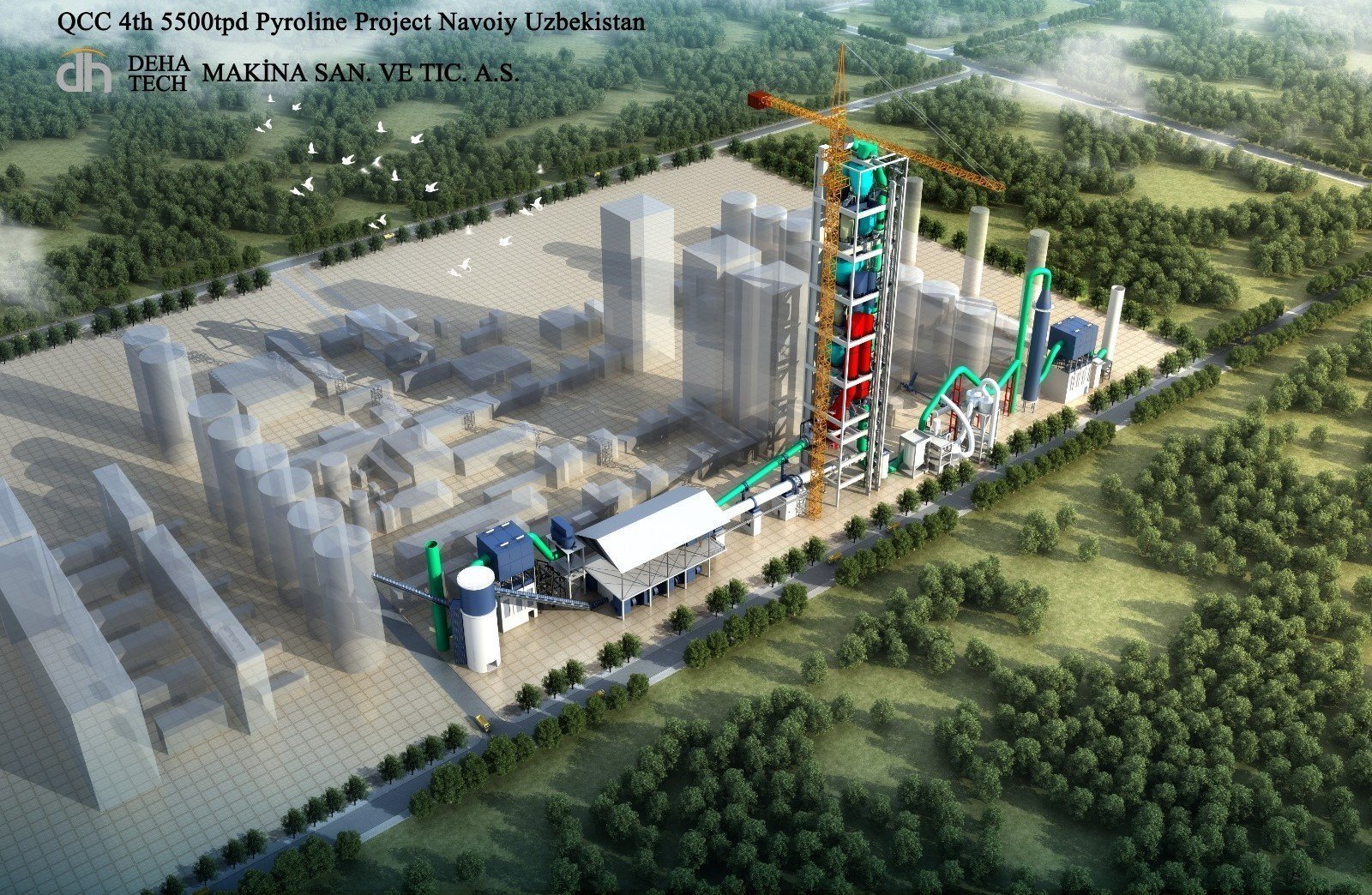

High operational safety, low production costs, ideal energy efficiency – Deha Tech sets standards for the gypsum sector with production plants

As one of the few companies in the world, Deha Tech supplies complete plants for the manufacture of gypsum plaster, gypsum plasterboards and gypsum blocks including the buildings, infrastructure and logistics. The product range includes concept planning for market entry, construction planning and client staff training.

Deha Tech supplies both individual components as well as turnkey solutions.

Technological Gypsum Plants designed by Deha Tech We offer the most accurate and most suitable facilities for our customers by taking into account the characteristics of our customers, the current fuel type, capacity needs, market targets and facilities, production cost expenses.

Gypsum production plants will be designed specifically according to demanded capacities to be required in production and also final product specifications to be obtained.

The capacity of the plants can be increased by increasing the number of furnaces.

Deha Tech works on various parameters for all process equipments and machineries like dimensional accuracy, shapes, sizes and make sure end up satisfying the customers to the fullest.

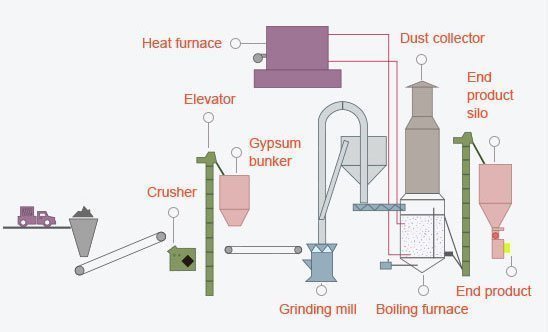

Our facilities consist of main units;

- Raw Material Crushing and Screening

- Calcined Rotary Kiln

- Grinding and Separation

- Dosing and Weighing

- Mixing

- Dedusting

- Perlite expansion

- Micronized Calcite Grinding and Decomposition

Gypsum Production Process has become an important study in terms of the product development and improvement of gypsum plant. Gypsum has many types with usages in industrial areas. Such as;

Types of Gypsum:

- Plaster Gypsum

- Machine Gypsum Plaster

- Satin Gypsum

- Plasterboard Plaster

Usage Areas of Gypsum:

- Adhesive chemicals

- Agricultural chemicals (non-pesticidal)

- Building / construction materials / wood and engineered wood products

- Cement industry; Portland-cement retarder

- Fillers

- Gypsum industry; gypsum board, bond and plaster

- Polishing powder

- Boards (white pigment, filler, drier) paper filling, surface coating)

- Drying of industrial gases, solid materials and many organic liquids