Deha Tech with over 20 years of experience, offers time tested robust Dampers, Ducting and Expansion Joint to achieve a low maintenance design life. All are fully assembled, cycled, and tested in the shop before shipment.

Our engineering and design team is involved with every project to ensure the structural and dynamic integrity of our products.

Services:

- Standard Design considerations

- High safety factor on drive sizing

- Maximum of 60% of yield stress on all components

- Modelling to minimize pressure drop frame deflection and blade deflection high quality components

- Trademarked material selection to minimize maintenance

- Quality Management System

Our Dampers:

Constructed with carbon steel, stainless steel, alloy, and/or corrosion resistant materials our dampers are capable of withstanding temperatures up to 1800°F and the most chemically punishing environments.

Type of Dampers:

- Slide Gate Damper

- Louver Damper

- Diverted Damper

- Stack Isolation Damper

- Wafer Damper

- Poppet Damper

- Radial Vane Damper

Deha Tech manufactures heavy duty low leak slide gate and zero leak slide gate dampers to provide isolation for flue gas and air systems. Slide gates, also referred to as guillotine dampers, are required to isolate systems for maintenance or for bypass purposes.

Our Expansion Joints

Also We offer designs specifically engineered for every application and have supplied expansion joints in Boilers, Incinerators, Fans,

Environmental Control Equipment such as FGD and Fabric Filters.

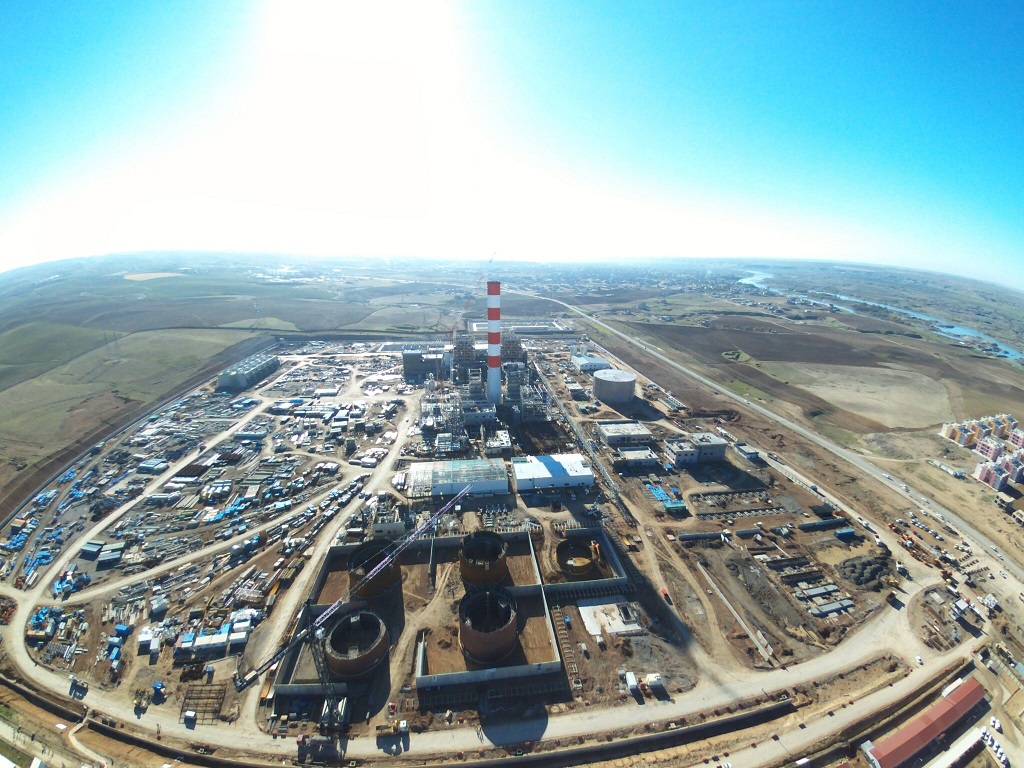

Our expansion joints can be found in Fossil Fired Power Plants, Refineries, Cement Plants, Steel Mills, Pulp & Paper Plants, and Gas Turbine Applications throughout the world.

The design parameters which influence the performance of any expansion joint and which must be defined for proper design analysis include:

- Movements

- Design, Operating Temperature

- Design, Operating Pressure

- Flue Gas Composition

- Adjacent Ductwork Configuration

Expansion joints come in a variety of materials for instance they can be a bellows type where they are formed from a single piece of metal and allow movement of the ducting.